BOWEI DIE CASTING DESIGN

Bowei strives to make "long life, low fault, easy to disassemble, high efficiency" mold.

BOWEI DIE CASTING DESIGN

Bowei strives to make "long life, low fault, easy to disassemble, high efficiency" mold.

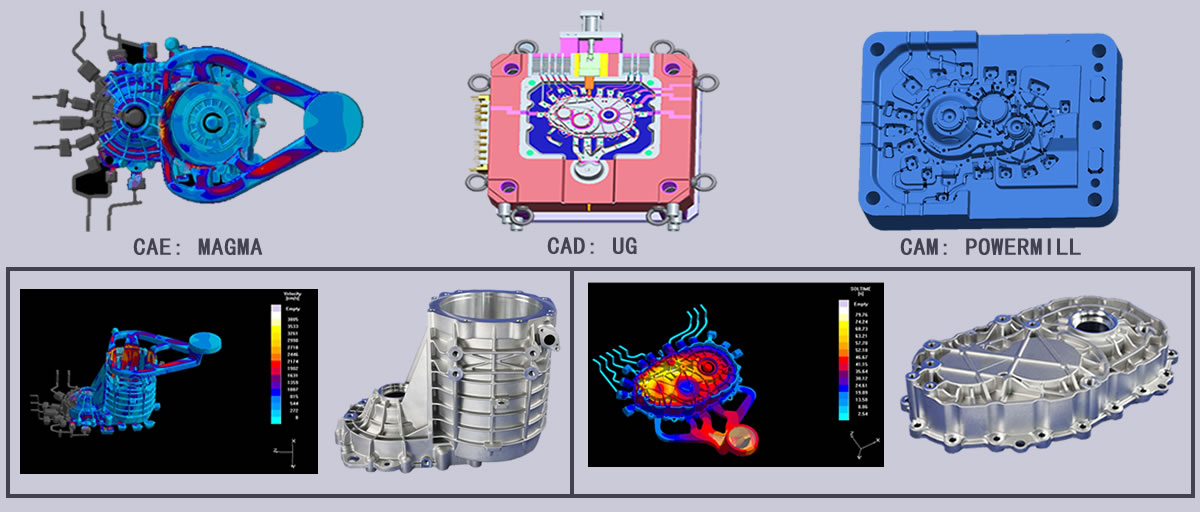

BOWEI MOLD DESIGN TEAM

◆Computer Aided Design(CAD)AUTOCAD、UG、PRO/E ◆Computer Aided Engineering(CAE)MAGMA ◆Computer Aided Manufacturing(CAM)POWERMILL

【Scientific calculation, repeated test and simulation of springback and surface defects, instead of repeated test, to improve the life of the mold, reduce the development cost.】

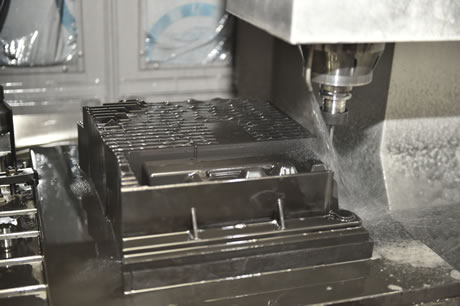

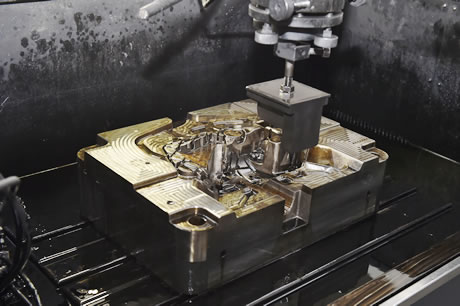

MOLD MANUFACTURING AND QUALITY TESTING EQUIPMENT

AFTER-SALES SERVICE

Make every effort to provide customers with the most satisfactory products and services.

Ningbo Bowei die casting Techology Co.,Ltd.

Address:No.255,xizhihe road,chunxiao industrial park,beilun district,ningbo,zhejiang

TEL:+86-574-86097620 FAX:+86-0574-86097625

Phone: +86-18888667299

Email: market@bwmjyz.com